Intro

Many important bulk behaviours of the granular materials can be explained starting from a micro-mechanical standpoint: plasticity, liquefaction, critical state, anisotropy, jamming, ratcheting, shear bands are some of them.

To study these aspects we can use particle-based numerical tools as well as special experimental facilities.

Schneebeli apparatus

The Schneebeli apparatus is a smart way to show the behaviour a granular material. It is constituted by several wooden dowel pins arranged in a box. Lateral walls can be fixed or moved to obtain different stress-strain conditions.

With this physical model, it is possible to study the typical failure mechanisms of foundations, the emergence of the active and the passive wedge in retaining walls, as well as to study particular interaction problems in 2D conditions. Using strain-controlled or stress-controlled walls we can also simulate simple biaxial tests. Each grain can be easily tracked with its translational and rotational movement by means of photogrammetric techniques.

Inspecting grains

X-ray tomography can be used to zoom into granular soils. X-rays are strongly attenuated as they pass through solid particles. Particular X-ray tomographic equipment is needed for this purpose.

Measuring micro-forces

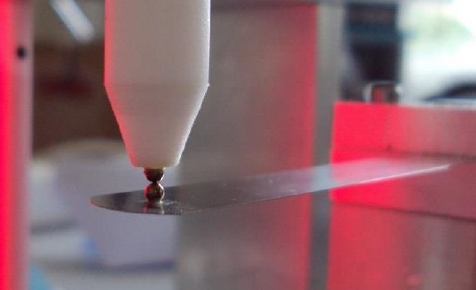

Contact forces are intense forces that develop at the contact between grains. They are difficult to measure since they span several orders of magnitude, they are internal forces and they may evolve quickly during stress-strain loading conditions.

Capillary forces also span orders of magnitude but they can be estimated with optical techniques aimed to measure the mean curvatures and the contact angles at the liquid-solid-air interfaces.

Measuring displacement

Measuring vibrations

Measuring pore water pressure

Pore water pressure affects the distribution of stresses in the soil. However, where the water domain is not connected very different pore pressure values can be measured like in the case of pendular and funicular regimes .

The particle-based numerical approach

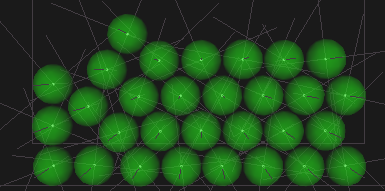

Micromechanics can also be studied using particle-based numerical tools like the Discrete Element Method which allows describing the material as a collection of solid grains and a collection of evolving interactions.

From numerical simulations, we can display the contact force distribution, the chain network, the rotations, the sliding phenomena as well as measure local properties like the porosity distribution.

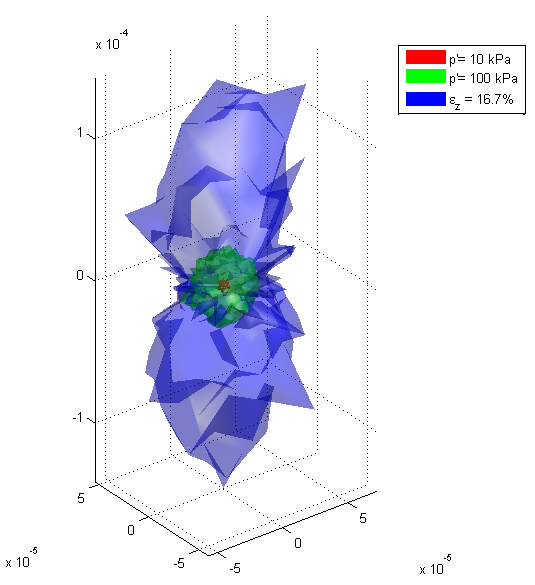

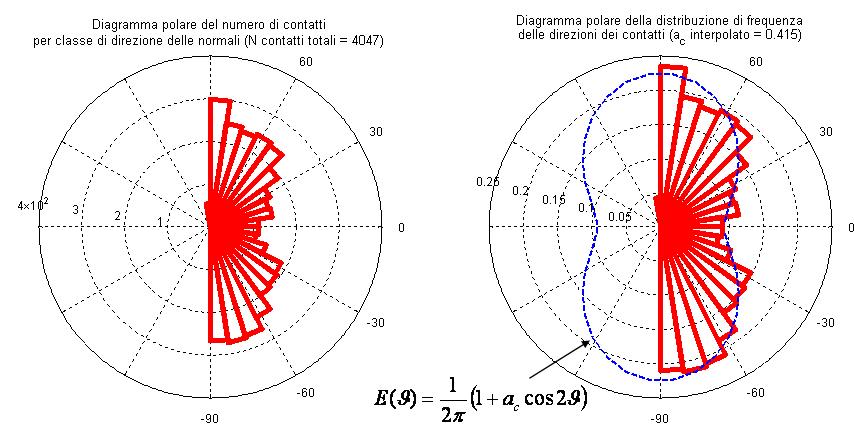

For example, this is the ‘2D’ contact distribution after the shear phase in a DEM cubic triaxial test assuming axial-symmetric conditions.

And this is the 3D plot of the normal force distribution